Next-Gen Porous Polymer Technologies: U.S. Advances in Sintering, Morphology Control, and Commercialization

Introduction: A New Era for Porous Polymers In recent years, porous polymers have moved from being specialty filtration materials to becoming a foundation for advanced technologies. The United States, with its strong research ecosystem and manufacturing base, has emerged as a leader in refining the science and scaling the industry. The focus today is on…

Introduction: A New Era for Porous Polymers

In recent years, porous polymers have moved from being specialty filtration materials to becoming a foundation for advanced technologies. The United States, with its strong research ecosystem and manufacturing base, has emerged as a leader in refining the science and scaling the industry. The focus today is on three interconnected areas: sintering innovations, morphology control, and the pathways to commercialization. Together, these advances are turning porous polymers into strategic materials for medicine, energy, and environmental sustainability.

Advances in Sintering: Precision at the Microscopic Level

Sintering, the process of bonding polymer particles under heat and pressure, is the cornerstone of porous polymer fabrication. The challenge has always been to achieve structural stability while maintaining precise pore networks. U.S. research groups have recently introduced several improvements:

Controlled Temperature Profiles

Traditional sintering often resulted in uneven bonding and pore collapse. New temperature gradient systems now allow manufacturers to fine-tune heat application, preserving pore integrity and enhancing mechanical strength.

Particle Engineering

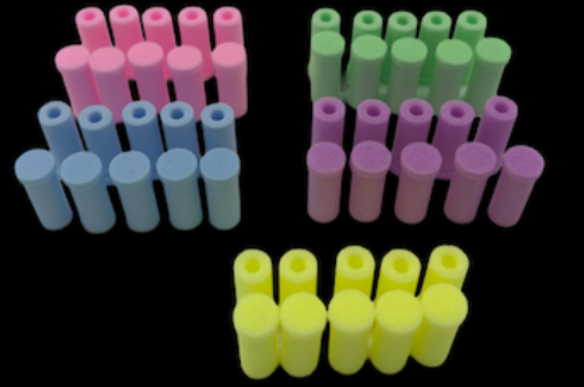

American laboratories are also experimenting with engineered particle distributions. By mixing micro- and nano-scale polymer beads, researchers can achieve dual-porosity systems that handle both bulk flow and fine filtration simultaneously.

Hybrid Sintering Techniques

Beyond thermal sintering, U.S. innovators are combining laser-assisted sintering and additive manufacturing with conventional methods. This hybrid approach offers unprecedented precision in pore geometry and makes custom-designed porous structures feasible for small-batch, high-value applications such as medical implants.

Morphology Control: The Key to Functionality

While sintering determines whether a porous structure is viable, morphology control defines its performance. In porous polymers, morphology includes pore size, connectivity, orientation, and distribution.

Tailored Pore Sizes

U.S. researchers have developed ways to control pore size distribution through chemical foaming agents, templating techniques, and advanced molding. Uniform micropores, for instance, are critical in medical diagnostics where fluid flow must be consistent and repeatable.

Gradient Structures

Emerging fabrication processes now create materials with pore size gradients—small pores on one side, larger pores on the other. This structure enables multifunctional devices, such as filters that first block large particles and then regulate gas flow, reducing the need for multiple components.

Surface Morphology and Functionalization

Another U.S. breakthrough is the ability to functionalize pore surfaces with chemical groups. This allows porous polymers to selectively capture or repel specific molecules, making them suitable for advanced environmental sensing or controlled drug release.

Commercialization in the United States

From Lab Research to Scalable Production

The biggest test for porous polymer technologies is scaling from laboratory prototypes to mass production. In the U.S., this has meant significant investment in pilot plants that integrate precision sintering with automated quality control. Optical scanning and AI-driven defect detection are increasingly used to ensure consistent pore structures at industrial scale.

Industry Adoption and Case Studies

- Medical Devices: Companies such as Porex have expanded U.S. production facilities to meet rising demand for diagnostic components and controlled delivery systems.

- Energy Storage: Battery manufacturers are integrating porous polymer membranes to improve venting and safety. With domestic battery production receiving federal support, adoption is accelerating.

- Environmental Solutions: Startups are commercializing porous polymers in compact water treatment units, particularly for rural U.S. communities where infrastructure is limited.

Investment and Policy Environment

The commercialization drive is supported by strong U.S. policy incentives. Federal research grants through the Department of Energy and National Science Foundation have prioritized advanced materials. Meanwhile, venture capital funding for materials science startups has surged, signaling investor confidence in the economic potential of porous polymers.

Challenges to Overcome

Cost of Advanced Processing

While traditional porous plastics are relatively inexpensive, next-generation techniques such as laser-assisted sintering and gradient morphology control add cost. U.S. companies are working to balance precision with affordability, especially for large-scale markets like municipal water treatment.

Regulatory Approvals

Medical and environmental applications in the United States require strict compliance with FDA and EPA standards. The approval process, though critical for safety, can delay product launches and increase R&D costs.

Sustainability Concerns

Despite their durability and performance, most porous polymers are still petroleum-based. U.S. research is beginning to explore bio-based alternatives and recyclability, but large-scale adoption of sustainable porous polymers remains in early stages.

Future Outlook: Why the U.S. Is Positioned to Lead

The United States is uniquely suited to lead the porous polymer revolution for several reasons:

- Integration of Research and Industry: Universities collaborate closely with companies, speeding up the transfer of breakthroughs to market.

- Policy Support: Federal programs aimed at green energy, advanced healthcare, and sustainable infrastructure indirectly support porous polymer commercialization.

- Market Demand: With growing needs in diagnostics, clean energy, and environmental protection, U.S. industries provide fertile ground for adoption.

Analysts forecast double-digit growth in the U.S. porous polymer sector over the next decade, with the greatest opportunities in customized medical devices, energy storage components, and sustainable water treatment solutions.

Conclusion: The Quiet Power of Engineered Porosity

Porous polymers are no longer just background materials; they are becoming strategic enablers for the U.S. economy. Advances in sintering and morphology control have unlocked new levels of performance, while commercialization pathways are proving that these materials can scale. Although challenges of cost, regulation, and sustainability remain, the United States is charting a clear path forward.

As researchers and companies continue to refine the science and expand the markets, porous polymers stand poised to reshape industries quietly but decisively—an invisible technology with a visible impact on the future.